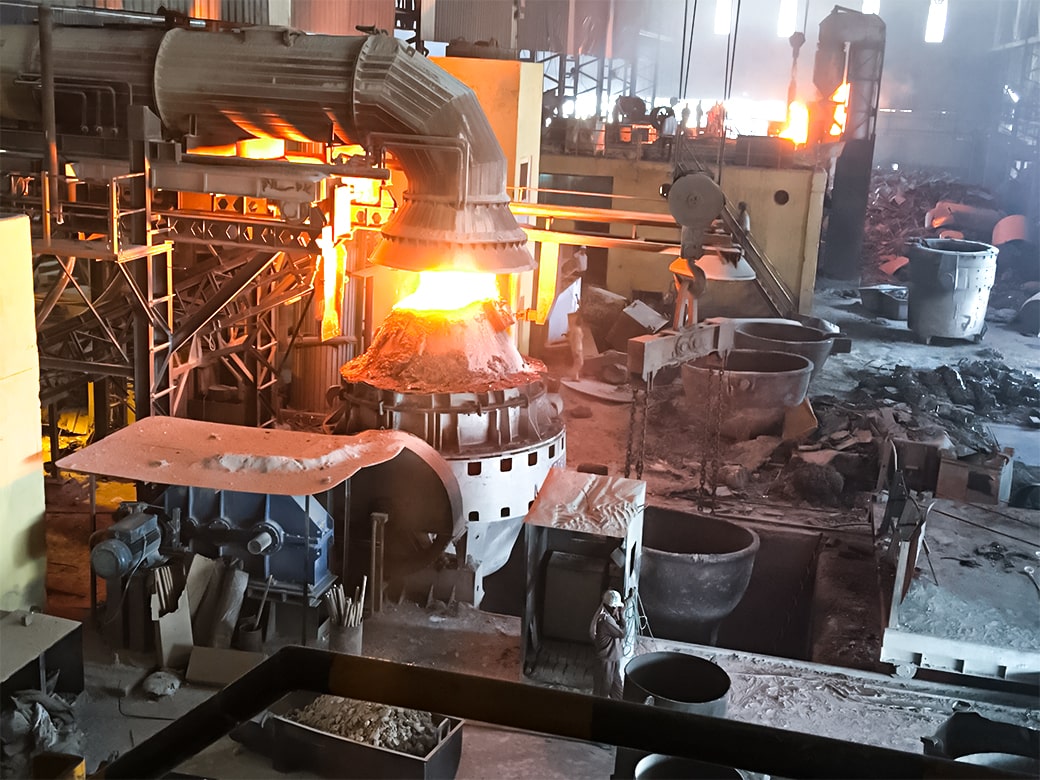

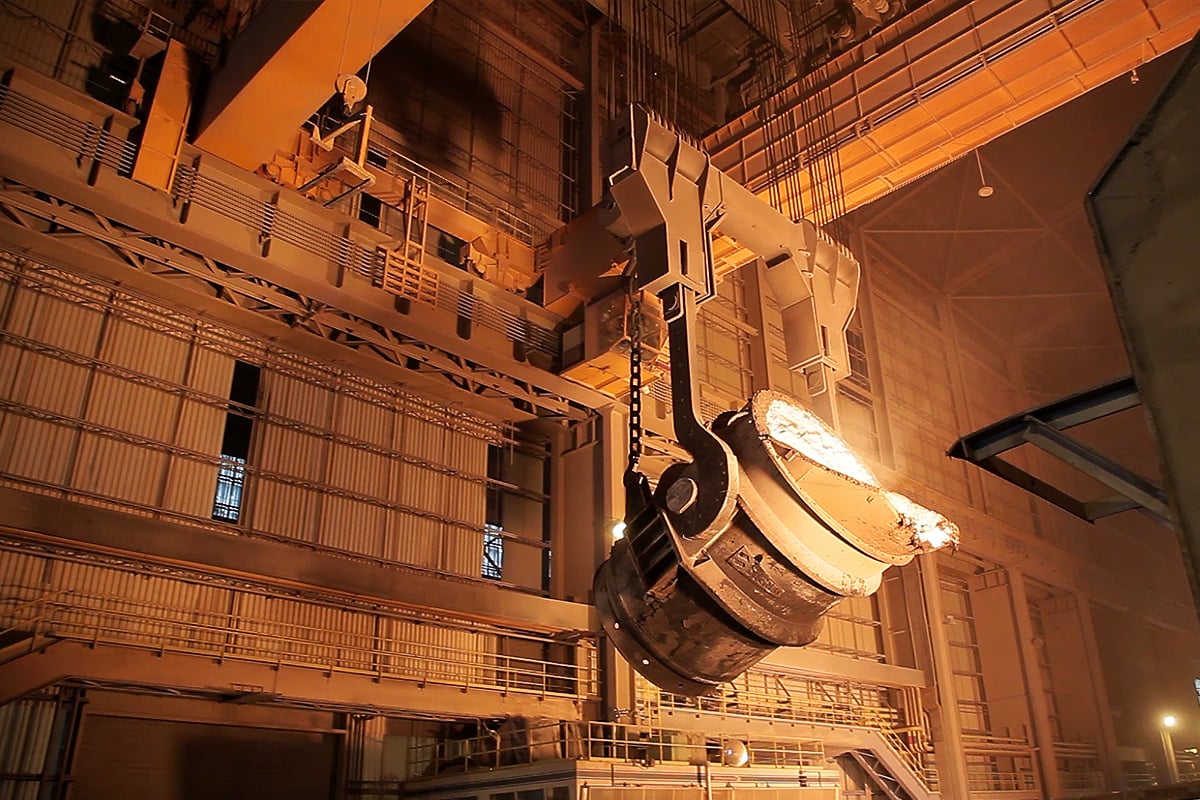

We specialize in manufacturing Steel Plant Equipment, Heavy and Technological Structures, Chimneys, Tanks, Vessels, and Customized Engineered Solutions. Our products are designed with a strong focus on structural integrity, precision fabrication, and long-term performance to meet the demanding requirements of steel, process, and heavy industrial applications.

At Ashutosh Engineers, every project is executed through a disciplined and well-defined workflow to ensure technical accuracy, quality assurance, safety, and timely delivery. Our project implementation process is designed to handle complex steel plant and heavy industrial fabrication requirements.

The point of using Lorem Ipsum is that it has more-or-less packages normal point of using.